Optimizing Inventory with the Power of AI

Inventory management is a critical aspect for businesses – those that are required to store products for the ultimate purpose of sales. Stocking the right number of goods at the right place and time, taking into consideration the scenarios of demand and supply is vital in order to fulfil consumer expectations in a timely manner, reduce wastage, stay efficient, and in turn, earn substantial profits. Needless to say, the advent of breakthrough technologies such as Artificial Intelligence (AI) has simplified and revolutionized inventory management, enabling business owners to act diligently and optimize their stocks, right from the manufacturing stage till product distribution.

Uncertain Times Call for Stronger Measures

We are in the midst of uncertain, tough times led by Covid-19, which took businesses by surprise and jolted the operations of many. Ever since, demand and supply have been prone to constant fluctuations and consumer behaviour is seen to always be always new turns. Understanding and optimizing inventory has emerged as a grave challenge, and businesses are actively on the look-out for solutions to effectively track and manage their stocks. Artificial Intelligence, with its potential to churn and distil large volumes of data, provides cutting-edge inventory insights and visibility to businesses, enabling them to enhance their revenues, customer experience and brand image.

AI’s capability to leverage large swathes of real-time inventory control dynamics that affect inventory stock levels differentiates it from traditional tools. AI can predict scenarios, recommend actions and even act — independently or with human approval. Take the example of a digital twin with a global view of all suppliers, manufacturers, transportation, warehouses, and retailers. Data from IoT devices such as GPS and RFID tags, business applications like ERP and WMS, and third party sources can be interconnected to model, monitor, and manage real-world supply chain environments, giving a real time view into product requirement.

The Positive Impact of AI-Led Inventory Optimization

Let us understand how the use of AI can provide positive outcomes across various scenarios in inventory optimization.

a) Analysis of consumer shopping behavior – In today’s unpredictable times, the buying behavior of the consumer is no longer constant. For businesses, it means staying agile and alert at all times to determine what will approve to the consumer at any given point of time. AI, with its outstanding abilities, intelligently slices the wealth of consumer data, including their purchase history, browsing patterns, social media acts, etc to accurately catch the pulse of the consumer behavior. These powerful behavioral analytics empowers businesses to determine their stocks and quantities effectively.

b) Accurate prediction of demand – The multiple datasets generated by businesses are intelligently harnessed by the AI technology to identify forthcoming market demand patterns with greater ease and accuracy. With Machine Learning (ML), real-time data can be easily leveraged to accurately predict demand and thereby determine how much inventory is actually needed to fulfill this demand. This helps businesses to take care of out-of-stock and over-stock issues intelligently. As per McKinsey, AI-powered demand forecasting has the potential to reduce supply chain errors by 30-50%.

c) Improved Warehouse Management – With the correct amount of goods being held at the warehouses, the space logistics and productivity get automatically optimized. Over-stocking entails huge costs and also eats chunks of storage space, which gets duly resolved with the help of AI-powered insights. As a result, the warehouse teams are able to operate efficiently, which brightens up the prospects of growth. McKinsey highlights that the use of AI reduces warehousing costs by approximately 10-40%.

d) Time Management – As the machines take over to process large amounts of otherwise inaccessible data, businesses are able to lay hands on important information such as expected time of arrival of any particular good/ goods, which might be out-of-stock. The same can then be communicated to the customers, which helps strengthen the brand-customer relationship.

e) Scalability – AI-based inventory management, with its accurate forecasting capabilities, allows businesses to respond instantly to any unexpected fluctuations in demand or supply, thereby allowing them to scale their stock up or down. This ability to act in real-time helps businesses to provide quick, quality services to their consumers and also help them clear their stock profitably.

The right solution tackles the problem in a right manner at the right time.

Enter, Affine

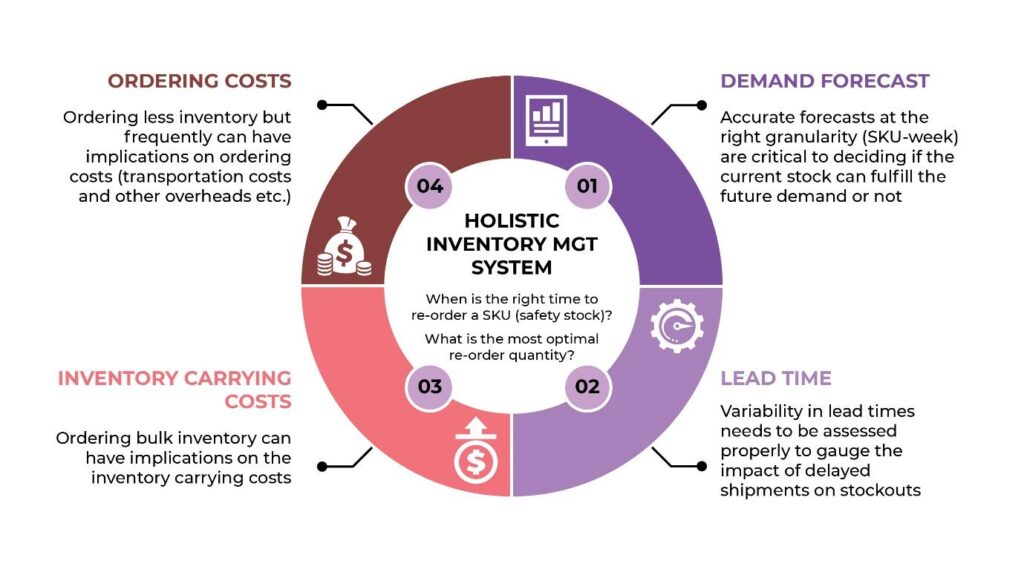

Affine’s new-age, AI-powered solution for Inventory Replenishment System helps businesses improve their inventory level efficiency by optimizing a wide range of variables.

- Demand Forecast – Accurate demand predicting algorithms used by Affine allow businesses to know what is needed at what time.

- Lead Time – Intelligence on lead time helps business combat issues such as delayed supply or low inventory.

- Inventory Carrying Cost – The cost of holding unwanted inventory automatically gets eradicated, since the AI-powered smart insights allow just the right inventory to be held in warehouses.

- Ordering Cost – Ordering just the right inventory keeps the ordering costs, including the overheads in control.

In fact, Affine has extensive experience in implementing AI and ML solutions across verticals in supply chain management. We have empowered a carrier fleet with route optimization, optimized inventory for a large shoe manufacturer store, demand forecasting for a coffee giant, and improving on-time delivery for an e-commerce giant. These are just the tip of the iceberg that is our experience and expertise in AI-led optimization for organizations across sectors and verticals.

Before we go…

Inventory optimization leveraging AI is all set to take the business world by storm. With the large swathes of data sets now available to organizations, their investment in cutting 4IR technologies, and unpredictable consumer behaviour are all leading this change from the front.

If you too are on the look-out for an advanced inventory optimization tool, experience the world of AI with Affine and elevate your inventory experiences.

About The Author(s):

The blog is a result of research efforts conducted by Affine’s Manufacturing CoE team, our Centre of Excellence which exists for the sole purpose of hyper-innovation in the manufacturing space. The Manufacturing CoE is a dedicated in-house team responsible to continuously innovate manufacturing solutions and services powered by AI, AE & Cloud capabilities. Our enterprise-grade solutions are new, hot, happening, futuristic and the next big thing in Industry 4.0.