Usher in Quality 4.0 With Digital Quality Management System

The technology revolution of the last decade is ushering in a new industrial revolution – it is called Industry 4.0. Disruptive technologies, exponential growth, superfast manufacturing are some of the key indicators of these new times. However, to truly stay true to the revolution and to make the most of it, manufacturers around the world need to invest in Quality 4.0. What is Quality 4.0? According to KPMG, “Quality 4.0’ is a state of transformation that references the future of organisational excellence and quality within the context of Industry 4.0. Quality 4.0 combines the capabilities of Machine learning, Artificial Intelligence, Cloud Computing and Big Data with conventional systems of quality management for driving continuous process improvement and for improving overall business performance.” The reason for Quality 4.0 is simple – in a world where consumers have unprecedented choice, errors and compromise on quality could cost organizations their reputation and revenue. At Affine, we believe in the power of Digital Quality Management System at the core of Quality 4.0.

Digital Quality Management System, Protecting Manufacturers’ Reputation and Revenue

Quality Management Systems (QMS) is a key element in Industry 4.0. All manufacturing organizations need it, as it enables manufacturers to electronically monitor, control and record into documents of their quality processes. This in turn ensures that their products are manufactured within high quality parameters, complying with all applicable standards, and do not contain any defects in the outflow of the product. In order to become a core element of Quality 4.0, a sound and strong Quality Management System takes into account people, process and technology to deliver the best manufacturing outputs.

A quality management system typically has three key aspects:

- Organize: Organizing is the process of translating policies that describes quality procedures, processes, instructions & segregation of the contents that are defined.

- Analyze: Analyzing is the process of transforming the policies into processes and instructions to achieve the computed defined standards.

- Finalize: Finalizing is the process of transcription that take actionable measures by systemic and methodical approach.

The Different Approaches and Scopes for Digital Quality Management System

Defect Detection, digital QMS for defect detection works with quick identification of defective or anomalous defects on the complex physical surfaces by leveraging the deep learning technology using advanced vision system. This helps the manufacturing sector reduce rejection costs. Detection of defects in early stages of manufacturing helps reduce operational costs.

With Data Analytics, digital QMS models achieve predictive quality data management capabilities by leveraging Artificial intelligence (AI), Machine Learning (ML), Natural language processing (NLP), Intelligent automations etc. These emerging technologies ease the production process and ensure that the end customer always receives defect-free products.

Digital QMS can be used on top of MES, ERP, LIMS, and other softwares to expand the capabilities within the organization that are strategic to business which provide complete visibility. The improved knowledge from these helps in new product design and development and effectively optimize the production process in the shop floor. The combination of digital QMS with other industry softwares gives real-time market evaluation with respect to various products, minimizes negative brand exposure and also decreases waste helping reduce costs.

The hallmarks of a sound Digital Quality Management System include:

- Global visibility across distributed operations

- Enforcement of process to ensure compliance.

- Event monitoring and early trend escalation

- Global risk management

- Automatic containment of suspect items

- Intelligent root-cause analysis

- Automated quality assurance

- Adaptable best practices

- Enterprise scalability

Digital Quality Management System in Action

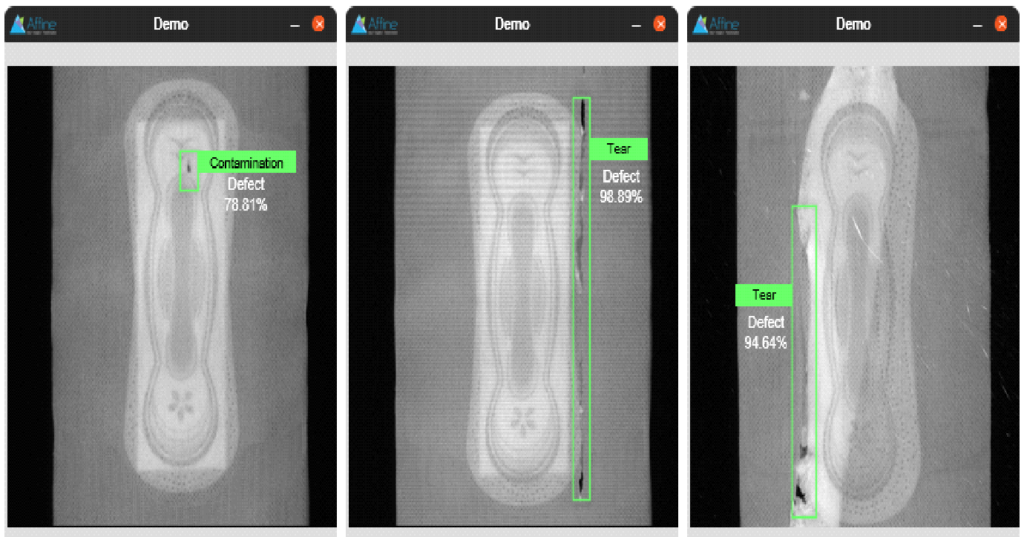

Affine’s Manufacturing Centre Of Excellence has a strong Digital QMS system in place for our manufacturing customers. We have delivered pathbreaking projects in this space. One of the examples is of Surface Defect Detection.

The femcare division of a leading CPG manufacturing company wanted to automate the manual process of detecting defects/faults during the production of the femcare products.

We leveraged Image Annotation to identify different type of defects and mismatches during the production process. We then augmented and boosted the number of images during preprocessing to create exhaustive training set. Multiple models were trained, and checked for accuracy and the best model was selected the based on the accuracy of outputs.

The output was consumed in the form of a web-based tool showcasing extent and type of damage to femcare products along with the respective tagged defect location on the product.

The process, although initially novel and complex, ensured that the final femcare products that the manufacturer produced were always in good condition, and without defects. With streamlined product defect detection processes using AI, the manufacturer achieved a 98.89% success rate in defect detection.

Before you go

The rapid growth in demand for Digital Quality Management System is being driven by the consumer demand for reliable products. As the world moves more and more towards internet-based sales, QMS is going to become increasingly critical for manufacturers as processing returns and exchanges will become a high cost center.

It is up to manufacturing organizations to invest in QMS well in time, in order to win the trust of their customers in the hyper-competitive era in which they now operate. Affine’s Manufacturing CoE is here to help. Write to us for a demo and we’ll get you started on your journey of Quality 4.0 in order to thrive in Industry 4.0.